class 100 clean room air change rate

USP 800 Cleanroom Hazardous Drugs HazCom Clean Room Designations Cleanroom. Grades A and B correspond with class 100 M 35 ISO 5.

Operating Room Ventilation Systems Recovery Degree Cleanliness Recovery Rate And Air Change Effectiveness In An Ultra Clean Area Journal Of Hospital Infection

Benchmark for ISO 2 ISO 5 facilities.

. In this case you can directly enter an ISO 8 cleanroom without an airlock. Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu. Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu.

7 rows FS Cleanroom Class. How to clean a Class 100 ISO Class 5 Cleanroom. Air flows through the entire cross-section of a clean zone.

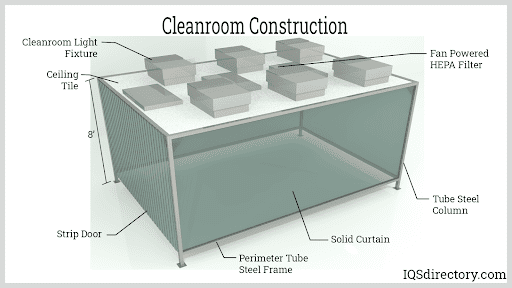

In addition to particle control the cleanroom is temperature and humidity controlled to 70F 45 RH. ISO Class 6 - 150-240 air changes per hour with a ceiling coverage of 25-40. Within our cleanroom design and construction process this is important in defining the quality of clean are in an ISO Clean room and various clean room designs that our company manufactures.

Uniform velocity throughout the entire space. Further in are the actual work spaces. A class 100 cleanroom maintains less than one hundred particles larger than 05 microns in each cubic foot of air space.

In Class 5 and below the strictest cleanroom classifications the air change rate is so rapid it is expressed instead as airflow velocity either in meters per second or feet per minute. Been laundered in a class 100 cleanroom using ultra-filtered water of 045 micron purity and HEPA-filtered air during moisture. A cleanroom must have less than 3520 particles 05 micron per cubic meter and 250-300 HEPA filtered air changes per hour.

To meet the same standard using the high-end air change recommendation 480hour requires 12 FFUs. And D air grades the number of air changes should be related to the size of the room and the equipment and personnel present in the room. The Only Fully Integrated Modular Solution With Sterile Air Filtration.

Large numbers like class 100 or class 1000 refer to FED_STD-209E and denote the number of particles of size 05 µm or larger permitted per cubic foot of air. I am investigating a contamination problem with a class 100000 clean room for a Medical devices plantI would like to know what is the recommended air change per hour for a class 100 000 cleanroom and its gowning area and where would i find the information to back this upAlso as there is increased traffic in the cleanrooms is there any way to counteract the. Sterile or hazardous compounding has a much different airflow requirement than a microelectronics cleanroom.

9 rows Class 100000 0005 0041 msec 1 8 ftmin 5 48. Environmental Control for ISO Class 1 thru 8 Cleanrooms. A properly designed clean room must have a high rate of air changes to scrub the room of particulates.

7 rows A cleanroom must have less than 3520 particles 05 micron per cubic meter and 250-300 HEPA. These cleanroom environments require air that is extremely clean so the constant changing of contaminant-free air is vital to maintain classification standards. ISO 7 Class 10000 0051 0076.

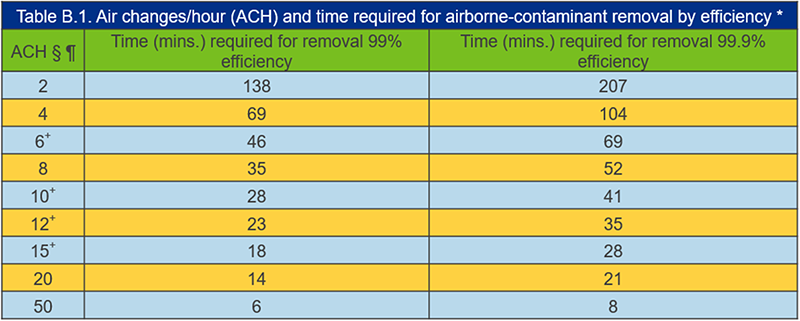

Of volume requires 6 FFUs. In a cleanroom depending on classification and usage air change occurs anywhere from 10 to more than 600 times an hour. Air change rates within primary compounding rooms vary between 12 30 ACH.

Hour that filtered outside air replaces the existing volume in a building or chamber. ISO 8 zone 1525 air changes per hour. Depending on the production process inside the cleanroom however you may have to add a gowning room.

Once the room is completed most specifications call for testing and certification. The space is about 40 feet by 40 feet and is separated into three main areas. Below is a table for the ISO 14664-1 cleanroom systems standards.

In a normal home an air-conditioner changes room air 05 to 2 times per hour. To meet the same standard using the high-end air change recommendation 480hour requires 12 FFUs. In unidirectional airflow cleanrooms calculate air change with average airflow velocity sampling.

The Air Change Per Hour is also an important criteria that needs to be met in order to be. ISO Class 4 - 400-750 air changes per hour with a ceiling coverage of 50-90. ISO Class 3 - 500-750 air changes per hour with a ceiling coverage of 60-100.

Grade C with class. A Class 5 room can have an air change rate of 400 to 600 times per hour while a class 7 room can change at 50 to 60 changes per hour. The GMP clean air grades and classifications define the environment in which sterile drugs and biological products should be.

ISO Class 5 - 240-600 air changes per hour with a ceiling coverage of 35-70. ISO 8 Cleanroom Class 100000 Cleanroom Lets assume that an unclassified space office or lab is ISO 9. A flow hood within the primary control area does in fact influence the overall air change rate of the room as a whole.

The Class 1000 side is first followed by the Class 100 side. We built our cleanroom in 1996 inside our existing fab shop. Cleanrooms are classified according to the number and size of particles permitted per volume of air.

Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu. Airflow velocity is independent of the ceiling height. First a small gowning room was built at the entry.

The two workspaces are separated by a static. Cleanroom Air Exchange Calculation Variables. Of volume requires 6 FFUs.

Ad Environmental Control for ISO Class 1 thru 8 Cleanrooms. If the supply of the air by HVAC system in one hour is equal to the volume of the room then it.

Iso 7 Clean Room Manufacturer Class 10000 Clean Rooms

Iso 14644 Cleanroom Classification Classes And Requirements

How Many Air Purifiers Do I Need One For Every Room Really

Air Changes Per Hour Calculator Cfm Based Formula Examples

Improve Your Eco Friendly Home Environment Https Www Airpurificationtech Com Improve Eco Friendly Home Environment Home Home Comforts Eco Friendly House

Pharmaceutical Microbiology Calculation Of Air Changes And Air Velocity

Clean Rooms An Overview Sciencedirect Topics

Blue Pure 211 Auto Air Purifier For Up To 550 Ft In 2021 Indoor Air Quality Air Quality Sensor Large Living Room

Iso 7 Clean Room Manufacturer Class 10000 Clean Rooms

Building Ventilation And Filtration Facilities Management

Air Background Environmental Guidelines Guidelines Library Infection Control Cdc

Operating Room Ventilation Systems Recovery Degree Cleanliness Recovery Rate And Air Change Effectiveness In An Ultra Clean Area Journal Of Hospital Infection

Role And Calculation Of Air Changes Per Hour In Clean Room Area Pharmaceutical Guidelines

Operating Room Ventilation Systems Recovery Degree Cleanliness Recovery Rate And Air Change Effectiveness In An Ultra Clean Area Journal Of Hospital Infection